“If you’re going to do something, do it right.”

Arla Foods Ingredients offers specialized protein powders that make a world of difference in functional food applications. With years of testing, they’ve perfected high-protein snack solutions, making them soft and luxurious rather than hard or chewy.

In a world where business runs from deadline to deadline, chasing quarterly revenue goals with reckless abandon, we sometimes forget the old adage in the sentence above. But when it comes to protein bars, high-protein snacks, and functional foods, truer words have never been spoken.

Compared to the typical supplement launch, there’s a lot more on the line when developing “better for you” foods. The competition’s never been stiffer, with protein-fortified snacks on the shelves that legitimately rival candy bars. Consumers simultaneously demand higher-quality, better-tasting, and healthier options — and the market is delivering on those demands.

Better Protein Bars Need Better Protein Sources

There’s one key piece that separates the winners from the losers in this field. Lost in the commotion of flavors, textures, and toppings in modern protein bars and brownies is the single most important part of the product — the protein itself!

Arla Foods Ingredients is shaking up the industry with clear whey protein isolates that actually taste good, but when do brands pick which one?

As consumers and brands have sorely learned, your average six-month old protein bar is entirely different from one that’s fresh out of production. After 12 months, most of them are headed to the bargain bin, and at 24 months, they’re basically paperweights. Even worse, we’ve also seen how mold can turn a protein brownie into a catastrophe.

Product deterioration and defects turn into returns from both customers and retailers, which turns into lost money, and worst of all, damaged reputation for the brand.

Time and again, industry formulators and food scientists have learned that not all protein powders are the same, especially when creating functional foods. In the world of protein bars, brownies, and cookies, you need materials that are soft, stable, bind well, properly hold moisture, and stay that way. These aren’t protein shakes — these are foods to be chewed, and they’re far more difficult to get right.

Arla Foods Ingredients: The Industry Leader in Proteins

Thankfully, there’s one company dedicated to the science of proteins that has several solutions to perfect the art of protein bar development: Arla Foods Ingredients.

A subsidiary of Arla Foods, the world’s fourth largest dairy company, Arla Foods Ingredients has established themselves as the world’s premier innovative milk-based protein supplier. We’ve covered Arla Foods Ingredients’ Clear Protein Solutions in the past, which includes Lacprodan® ClearShake, Lacprodan® ISO.WaterShake, and Lacprodan® BLG-100.

ISO.WaterShake is a clear whey protein isolate ingredient from Arla Foods Ingredients that brings an incredible taste and mouthfeel without the sticky texture and astringency of other clear whey ingredients!

At SupplySide West, we were even given a look at the future of protein, where the Arla Foods Ingredients team showed us the potential of their protein powders in both foods and beverages. After tasting a new protein brownie at the 2024 Arnold Sports Festival, we had to learn what made these bars different.

It turns out that Arla Foods Ingredients has numerous protein powders designed specifically for functional food applications. And when brands decide to use them, it makes a world of difference. This article covers these options, explaining the differences between them, and when brands and formulators should use each one.

Before diving in, sign up for our Arla Foods Ingredients news alerts, so that you get notified of new science and products utilizing their innovations:

Subscribe to PricePlow’s Newsletter and Arla Foods Ingredients Alerts

Protein Bar Problems to Prevent

The days of blindly combining protein powders with some syrups and binders are long over. We now know that there are numerous pitfalls that can derail a functional food product launch:

Water Activity – This is the availability of water in a product, which affects its shelf life and safety. High water activity can lead to microbial growth and spoilage, while low water activity can result in a dry and crumbly texture.

Binders – Binders help hold the bar together, affecting its texture and chewiness. However, improper use of binders can make the bar too sticky or too hard, negatively impacting the consumer experience.

Glass transition temperature – This is the temperature at which the protein or other components in the bar change from a viscous and fluid state to a glassy, and more hardstate. It affects the texture and stability of the bar, particularly during storage.

Maillard reaction – This is a chemical reaction between amino acids and reducing sugars that occurs during cooking or storage, leading to browning and changes in flavor. While it can enhance taste, it may also reduce the nutritional value and alter the texture.

Hydrolysates – Protein hydrolysates are broken down proteins that are easier to digest. However, they can also lead to bitter tastes and affect the texture of the bar, making it softer throughout shelf-life. or more prone to moisture retention.

And not to forget, moisture loss, water migration, hydration, phase separation, reducing sugars, powder particles, pH, and especially which protein source to have in the matrix — all of which will impact the final protein bar.

As you can see, this is no longer beginner’s science — protein bar manufacturing has become a serious business, and brands need to take it seriously. Thankfully, Arla Foods Ingredients has kept all of these issues in mind when developing their protein products for functional foods and bars:

Arla Foods Ingredients Protein Solutions for Bars and Snacks

Arla Foods Ingredients provides a range of innovative solutions for enhancing the texture, taste, and nutritional profile of protein bars. They have four main protein powders and two texture enhancers to support brands and developers, regardless of whether they’re starting a new project or improving an existing product:

Nutrilac® PB-8420

Nutrilac® PB-8420 is the original Arla Foods Ingredients protein powder developed for the functional foods space. It’s a versatile and user-friendly protein solution that’s often described as a “plug and play” option due to its ease of use in various formulations.

Nutrilac® PB-8420 is 83% protein content by weight (dry matter), and combines high-quality milk proteins and hydrolysates to deliver incredible functional benefits that surpass the standard whey protein concentrates that were used before it.

One of its standout features is its robust shelf life of two years, though well-formulated bars with this ingredient often remain stable and effective well beyond this period. This makes Nutrilac® PB-8420 an excellent choice for manufacturers seeking a reliable, long-lasting protein ingredient for functional foods, particularly in protein bars and snacks.

Lacprodan® ISO.WheyBar

On the opposite end of the spectrum, Lacprodan® ISO.WheyBar represents the pinnacle of protein purity and quality in the functional food market. This premium ingredient is specifically designed for those who prioritize clean and high-protein macros in their dietary regimen, seen more often in the highly-demanding sports and active nutrition markets.

Comprising 91.5% protein by dry matter, Lacprodan® ISO.WheyBar blends speciality whey protein isolate, milk proteins, and hydrolysates that is designed for producing premium protein bars and other similar applications, that have high content of whey protein isolate and an excellent texture.

This makes it ideal for the more performance-driven consumers who demand the absolute best in protein supplementation. Beyond its impressive nutritional profile, Lacprodan® ISO.WheyBar is formulated to ensure stability and consistency, offering a reliable solution for creating high-protein bars and snacks that maintain their texture and taste over time.

Lacprodan® SoftBar

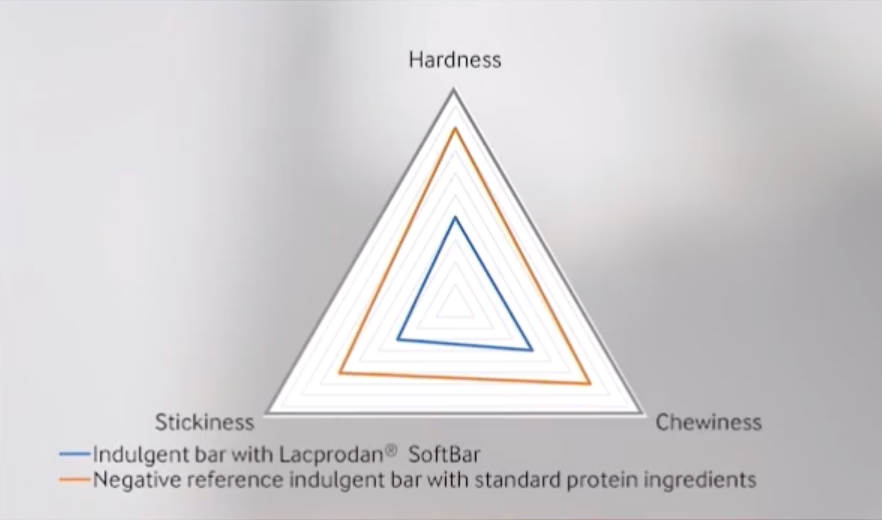

Lacprodan® SoftBar, with 88% protein by dry matter, is designed for creating the softest textures in high-protein snacks and bars. This protein solution excels in maintaining a tender and indulgent texture throughout the product’s shelf life, making it ideal for more challenging bar productions.

SoftBar’s versatility extends to compatibility with popular ingredients like peanut butter, making it a suitable choice for keto-friendly products. This ingredient is perfect for manufacturers aiming to create indulgent protein bars with a soft texture and superior taste, addressing common issues like textural deterioration and firmness.

Lacprodan® SoftBar is particularly effective in products like protein brownies, providing a pleasant mouthfeel and taste experience that appeals to consumers. Its formulation includes high-quality milk proteins and hydrolysates, ensuring not only a high protein content but also excellent solubility and stability.

Lacprodan® EasyBar

Lacprodan® EasyBar stands out as a versatile and highly functional protein solution, offering 85% protein by dry matter. This ingredient is specifically developed for co-extrusion processes, making it ideal for a wide range of protein bars and snacks. EasyBar combines high-quality milk proteins and hydrolysates to ensure a soft texture throughout the product’s shelf life. Its unique formulation is particularly effective for maintaining softness, making it suitable for indulgent protein bars and snacks that require a consistent, pleasing texture.

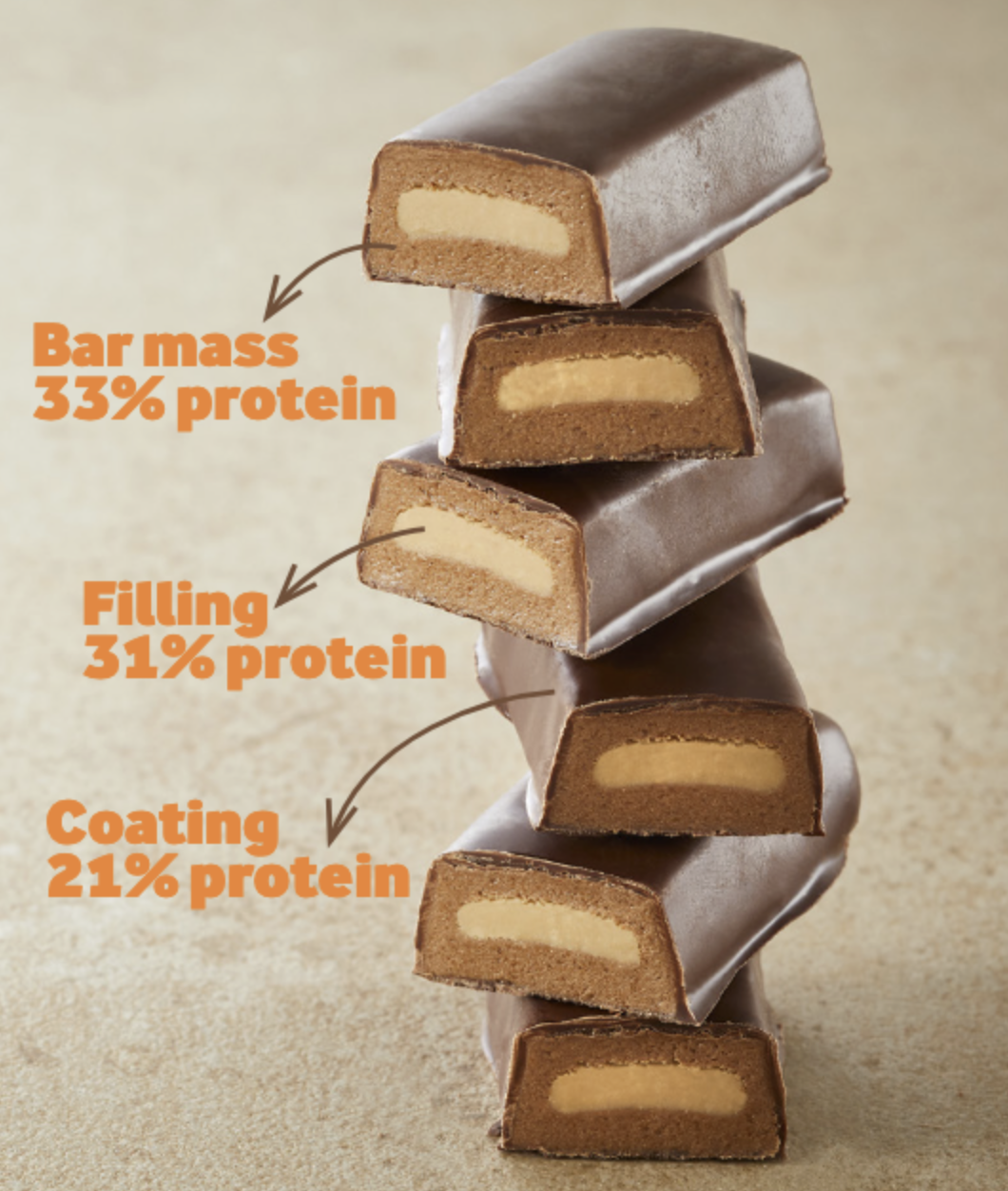

When it comes to layered, multi-textured protein bars, Lacprodan® EasyBar is a must-use, especially when seeking to achieve a high protein content in every layer. It’s not only designed to deliver that high protein content, but also to provide a soft and enjoyable eating experience, especially in more complex product formulations such as multi-layered bars.

Whether paired with rich flavors like chocolate or creamy ingredients such as peanut butter, EasyBar ensures that the final product remains appealing and high-quality. This makes it a top choice for manufacturers aiming to create versatile, soft, and indulgent protein snacks.

Arla Food Ingredients’ Texture Enhancers

Arla Foods Ingredients’ capabilities go beyond raw materials for new protein bar projects — they can also enhance the texture of existing products. They have two texture enhancers that can be swapped into existing recipes to improve texture and/or replace maltitol:

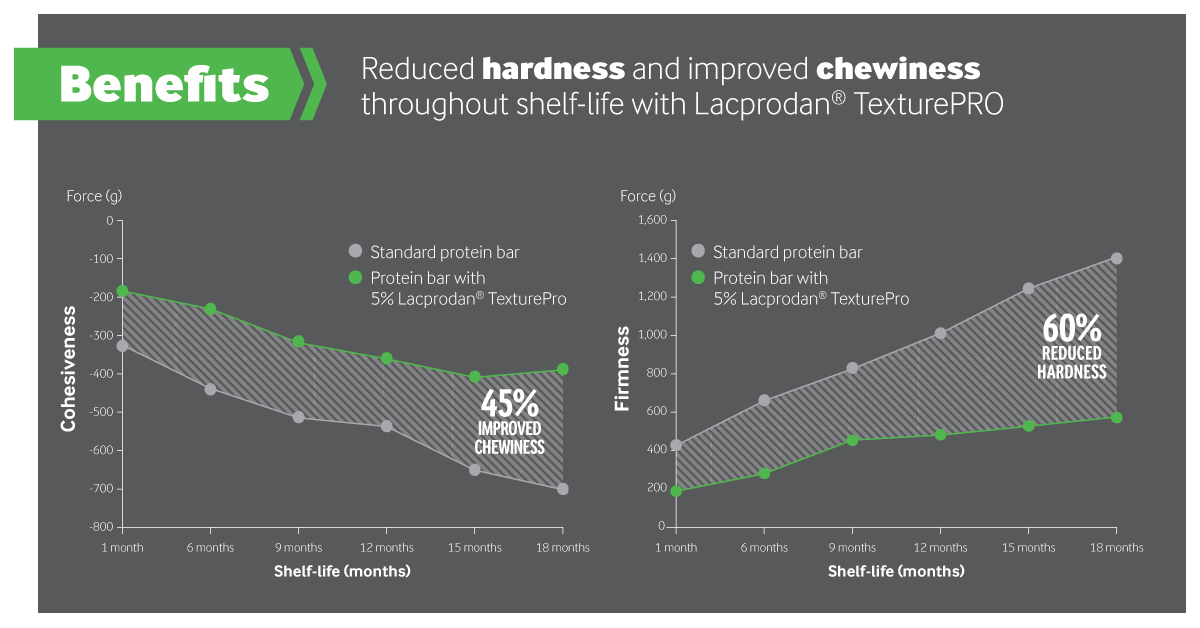

Lacprodan® TexturePro

Lacprodan® TexturePro is designed for protein bars and can be used to eliminate the need for maltitol, a commonly-used sugar alcohol in sugar-free and low-carb products that functionally brings softness. The goal is to improve the texture of protein products without maltitol, which can cause digestive issues and GI distress for some consumers.

Arla Foods Ingredients suggests swapping out 1-5% of the existing bar’s composition with TexturePro to achieve significant texture enhancements. This solution can help maintain the texture and quality of protein bars while reducing the sugar alcohol content, making the product more appealing to a broader audience — without necessitating an entire reformulation.

Lacprodan® HYDRO.PowerPro

Lacprodan® HYDRO.PowerPro is a whey protein hydrolysate developed by Arla Foods Ingredients, designed to offer the benefits of traditional whey protein hydrolysates without the typical bitter taste, which is often a barrier to consumer acceptance.

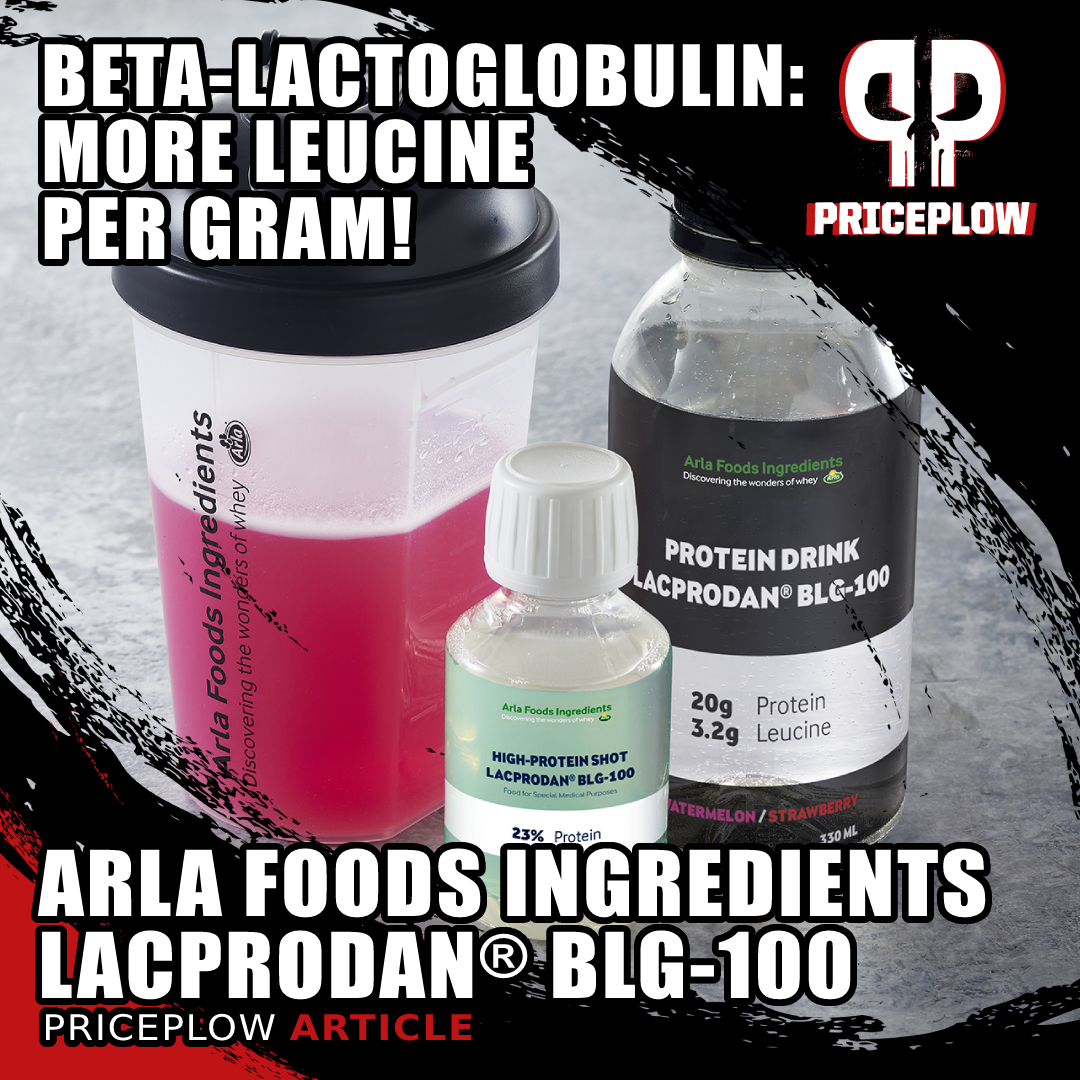

Arla Foods Ingredients Lacprodan® BLG-100 is a pure beta-lactoglobulin protein powder that takes clear proteins to the next level with a higher ratio of leucine than whey protein isolate!

This product has been specifically formulated to be 50% less bitter than other hydrolysates on the market with a similar degree of hydrolysis (21-27%). HYDRO.PowerPro can be used in protein bar formulations, by swapping out 2-5% of the existing bar’s composition and improving the shelf-life over time with a more soft texture.

These ingredients are designed to improve both the nutritional and texture of sports protein bars, making them more appealing to consumers, without disrupting an entire formulation that’s close to market or already on the market.

Further, these premium-quality ingredients are non-GMO (not genetically modified through the use of modern biotechnology) and contain no pesticides or antibiotic traces. Kosher and Halal certifications are available as well.

Taking protein bars seriously

Watch the webinar titled Protein Bars 360° – From Concept to Consumer, and you’ll see how seriously Arla Foods Ingredients takes the science — and art — of protein bar manufacturing. With their own in-house Application team and their own manufacturing test facility, they have the equipment and know-how to produce incredible treats, including many of the ones that they sample at numerous industry trade shows like SupplySide West.

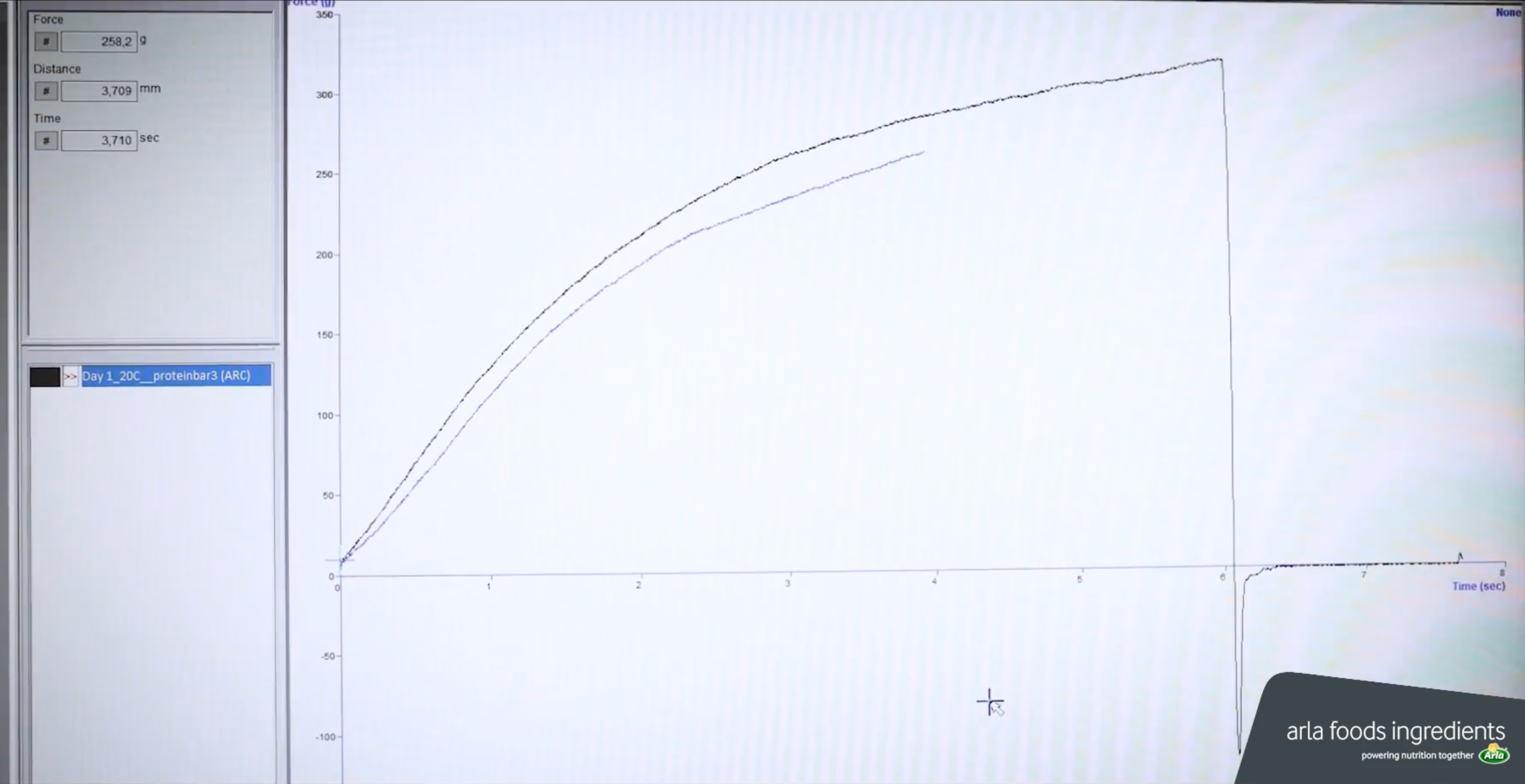

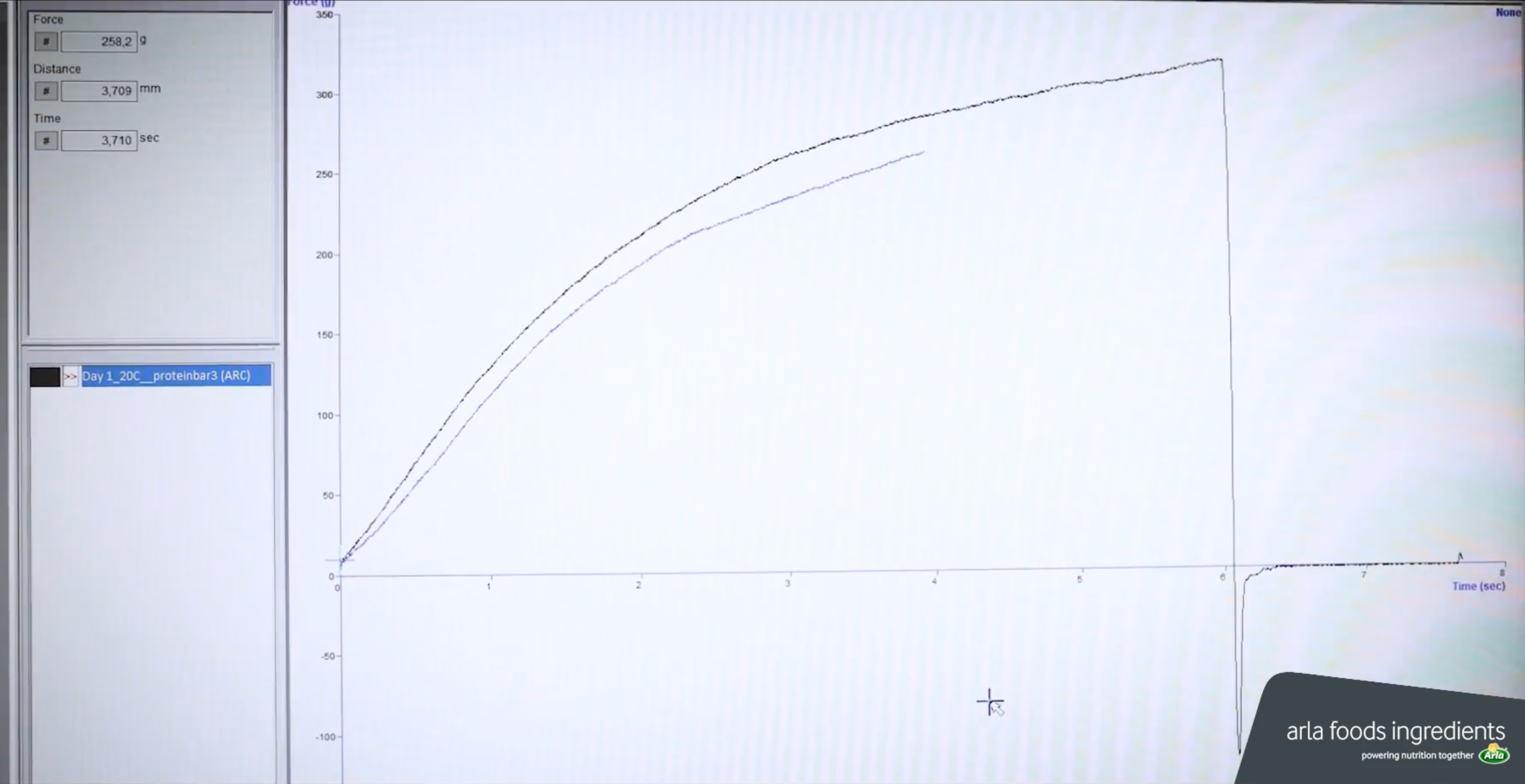

Case in point, Arla Foods Ingredients has equipment to test the hardness, correlated to the eating experience. They’ve define the consumer threshold for protein bars, and developed proteins that stay well below that for two years or more!

A Bite Force Chart courtesy Arla Foods Ingredients. See their Protein Bars 360° webinar to learn more.

To support customers big and small, Arla Foods Ingredients develops recipes together with their customers, and some are available for use in their literature. Developers can take them, tweak them, add their preferred flavors, test them, and have a product destined for long-term success with minimal work.

Arla Foods Ingredients’ Application team can also provide support with their ingredients, and can get closely involved with larger clients to ensure worldwide success.

Protein Bar Development: An Artform Just as Much as it is a Science

Protein powder is the main character of any protein bar. It can be soft and luxurious, or it can be the main reason why a product becomes hard or chewy. High-protein snack development is not just a science, it’s an artform that requires a lot of trial and error.

Thanks to Arla Foods Ingredients, you can get extra protein into your coating/enrobing as well! See their Protein Bars 360° webinar to learn more.

Thankfully, Arla Foods Ingredients has tested their ingredients for years, and has solutions for high-protein snack applications, whether it’s for a new project or improving an existing one.

This market has experienced significant growth that’s not going to slow. Consumers are increasingly demanding clean, high-protein, low-sugar options, and brands cannot withstand the negative financial impact and reputation of a batch of bars gone hard. Arla Foods Ingredients can support both ends of this problem set, helping you create the next innovation in functional foods.

Sign up for our Arla Foods Ingredients news alerts below, watch their Protein Bars 360° webinar, and see the main Arla Foods Ingredients Ready to Eat page for more information.